Tech Mahindra launches a sports cloud platform built on AWS to provide an immersive fan experience globally

SOURCE: HTTPS://WWW.MAHINDRA.COM/

NOV 27, 2023

How IoT Can Transform Supply Chain Management You are here:

SOURCE: EPSNEWS.COM

AUG 26, 2022

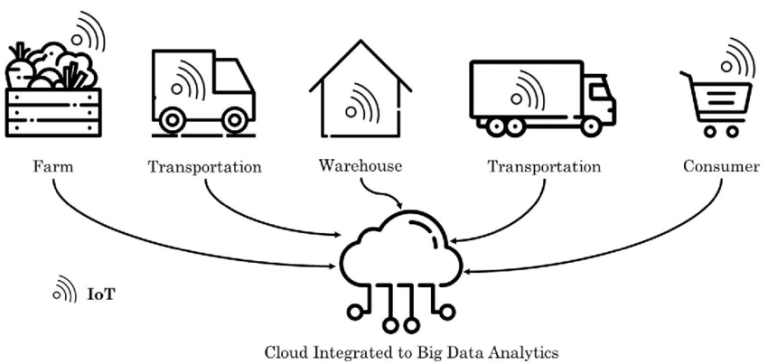

Tech businesses understand that integrating the Internet of Things (IoT) and the supply chain offers a smooth operation between many processes. Today, using IoT in supply chain management is a growing trend.

IoT is a network of physical devices equipped with sensors, software, and other tools to exchange data. Apart from sending and receiving information, the devices can monitor and report on the data. So, if data is transferred or exchanged between two devices without any human interaction, it’s using IoT.

IoT devices are usually connected to computer systems through data or Wi-Fi networks. They use global positioning systems (GPS) and other technologies to track and authenticate products and shipments effectively.

How does the system benefit an electronics company? The key benefits of IoT are:

The equipment uses advanced IoT sensors to measure various aspects of the surrounding conditions within the supply chain of goods. This includes location, temperature, humidity, light levels, movement, handling, speed of movement, and more. Electronic components are sensitive to humidity, heat and electro-static discharge, for example. IoT devices come in many forms, like RFID chips, smart devices, and mobile sensors.

IoT can provide real-time insights into the performance of the entire supply chain and logistics operations. Here are the main aspects of supply chain management that benefit from using the system:

The integration of IoT and the supply chain has the potential to resolve problems that arise when monitoring storage conditions. Some raw materials require specific storage conditions. Sudden changes in the temperature, humidity, or exposure to light or the atmosphere can affect the quality of products.

Goods like chemicals and food need to be stored in ideal conditions. Some IoT devices are equipped with alarm systems that would go off if the conditions are breached. This tactic makes it easier to track the quality of goods through the smart supply chain. Thus, it can save money by preventing the damage of goods due to improper storage conditions.

For example, if a company is expecting a delivery from an aluminum powder supplier, thanks to IoT, it can monitor the storage conditions of the substance. This is critical as aluminum powder releases flammable hydrogen gas when it comes in contact with, for example, water.

Moreover, the aluminum powder can react explosively with many chemicals. With IoT in place, the company can make sure the product will be kept in the right conditions at all times.

Integrating IoT with the entire trajectory of the supply chain allows a business to monitor the location of goods accurately. You can also track the speed of movement and predict when goods are expected to arrive.

Thanks to IoT devices with built-in GPS, businesses are aware of the real-time location of goods at all times. The connected devices and sensors can either be attached to the storage containers or products.

Real-time tracking allows companies to predict the delivery and, in case of delays, manage the situation accordingly. Companies can, for example, send an apologetic email to the end customer informing them about the delay beforehand.

Delivery delays often cost companies a lot of money. Geopolitical tensions or pandemic-induced disruptions are just a few reasons to cause unpredicted setbacks. Knowing the exact location and an estimated time when a product can be delivered saves companies valuable time and resources. Tracking the location of goods also helps manage the manufacturing pipeline as delays can be predicted.

Component traceability is also used as an anti-counterfeiting measure. Electronic components are often sold and re-sold into the open market where they can be tampered with. If the provenance of parts can be traced back to the factory, they are likely authentic.

Integrating IoT with the supply chain is beneficial for inventory management. Unlike manual inventory systems, IoT technology provides companies with more accurate and timely visibility of their inventory.

Smart inventory management using IoT systems facilitates real-time visibility across inventory, warehouse, production, and distribution centers. For instance, sensors installed on shelves transmit real-time inventory information to their management system. This reduces inventory costs by reducing manual labor.

Electronic components are often sold in kits that may include hundreds of SKUs. The accuracy of order-picking improves significantly with IoT data.

IoT devices can also alert warehouse operations when the supply of a particular stock is low so it can be ordered in advance. This tactic helps to prevent supply chain issues and missing delivery dates.

The illustration below shows how IoT sensors and connected systems can improve a business’ inventory management at the shop floor level:

Source: Researchgate.net

IoT data integrated into the ERP system can provide the most accurate real-time data to key decision-makers daily.

Integrating IoT and supply chain processes offers greater speed, scale, and accuracy of data exchange. The better the collaboration among the multiple stakeholders of a supply chain, the stronger the supply chain is.

IoT can transform the supply chain of a company’s management processes, like monitoring storage conditions, tracking the location of goods, or managing the inventory.

As IoT devices rely mostly on network connectivity to function well, it’s critical to maintain a good network connection. The devices need to transmit their positions to GPS satellites, while other devices may require Wi-Fi, Bluetooth, or other connectivity systems.

Finally, the IoT equipment should also be installed and powered correctly. The system should only be handled, attached, or removed by trained staff.

James Baker is a supply chain planning consultant based in Southeast Asia. In his spare time, he enjoys trying to learn new languages.

LATEST NEWS

Augmented Reality

Hi-tech smart glasses connecting rural and remote aged care residents to clinicians

NOV 20, 2023

WHAT'S TRENDING

Data Science

5 Imaginative Data Science Projects That Can Make Your Portfolio Stand Out

OCT 05, 2022

SOURCE: HTTPS://WWW.MAHINDRA.COM/

NOV 27, 2023

SOURCE: HTTPS://WWW.IOTTECHNEWS.COM/

OCT 27, 2023

SOURCE: HTTPS://WWW.THEDAILYSTAR.NET/CAMPUS/

OCT 01, 2023

SOURCE: HTTPS://WWW.IOTFORALL.COM/

SEP 11, 2023

SOURCE: HTTPS://WWW.IOTTECHNEWS.COM/

AUG 10, 2023

SOURCE: HTTPS://WWW.SCIENCEDAILY.COM/

AUG 11, 2023